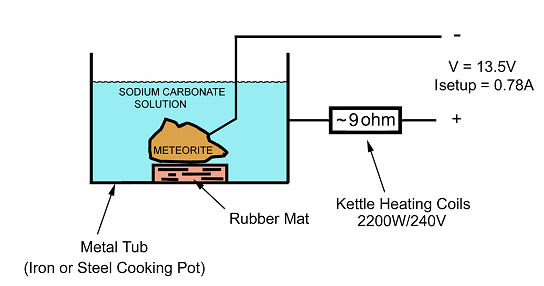

The corroded iron object is placed in a 5-10%w/v solution of sodium carbonate, Na2CO3. The specimen is wired to a cathode and placed in a clean iron or steel pot. The pot is then wired to an anode. A current is passed through the system by means of a DC power supply, which initiates the reduction cleaning. A diagram of this electrolysis cell can be seen below. The process is usually done in a lab environment using laboratory electronics, but a method of electrolytic cleaning at home using household equipment is also possible.

Removal of chloride ions at home is actually a fairly inexpensive process. All the chemicals can be purchased at your local supermarket. You would need distilled water and sodium carbonate.The priciest item would be the current limiting resistors, but these can be taken and modified from existing household appliances such as the heating coils of an electric kettle. These coils are rated at 2200 W with a resistance of 25-30 ohm. They are then wired in series to obtain the necessary current drop for the electrolysis cell. A regular 12volt DC power supply can be used.

The cleaning process itself can take as long as several days or even months to complete and it cannot be rushed. The length of cleaning time will also depend on the objects size and amount of chlorides in it. As the process takes place, positively charged metal ions are reduced and chlorides are drawn from the specimen by electrolytic attraction. Since the meteorite just sits in a bath solution, there is little else to do besides checking on it periodically to access its progress.

Once the water becomes dirty, the solution should be changed and the process repeated until the chloride concentration levels off. Change the solution every three or four days and repeat the process. Clean the iron meteorite and remove any rust particles with a soft wire brush before placing it in a new electrolyte solution. During the process, a small amount of hydrogen gas is produced and released from the specimen, as shown in the picture to the left. However, the amount of gas emitted is not enough to cause any problems, especially in a well-ventilated area.

Once the water becomes dirty, the solution should be changed and the process repeated until the chloride concentration levels off. Change the solution every three or four days and repeat the process. Clean the iron meteorite and remove any rust particles with a soft wire brush before placing it in a new electrolyte solution. During the process, a small amount of hydrogen gas is produced and released from the specimen, as shown in the picture to the left. However, the amount of gas emitted is not enough to cause any problems, especially in a well-ventilated area.

After the electrolytic cleaning has finished, the specimen should be stable and need no further treatment. Once done you can display the meteorite as prepared or etched with ferric chloride or 5% nitol in order to reveal the Widmanstatten patterns and Neumann lines underneath. In recent time, ferric chloride has become the etchant of choice. However, it requires further cleanup by being soaked in a 10% w/v sodium carbonate solution and then soaked in normal distilled water followed by an ultrasonic bath. Finally, the specimen should be sealed in a microcrystalline wax.